|

FG5000 Flywheel Grinders

Van

Norman Flywheel Grinders are the industry

leaders and provide the best return on your

investment. That's more profit! Van

Norman Flywheel Grinders are the industry

leaders and provide the best return on your

investment. That's more profit!

The FG5000 Flywheel Grinder is a solid,

well-built machine designed for grinding a variety

of flywheels. One of the most versatile grinders on

the market today, the FG5000 Flywheel Grinder

resurfaces automotive and import stepped flywheels,

truck flat flywheels, heavy duty truck stepped

flywheels center plates, and racing clutch

components. You can also grind automatic

transmission pumps and covers with the optional

ATP5000 Kit.

Fast, simple, accurate set-up - IN LESS THAN ONE

MINUTE!

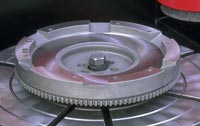

1 - Select the flange adapter and place it on the

rotary table

2 - Position the flywheel on the adapter

3 - Install the Centering cone and hold down the

bolt, then tighten

AS SIMPLE AS ONE - TWO - THREE! That's the entire

set-up. The flywheel sits on a precision ground

flange adapter ring assuring its position parallel

to the crankshaft flange. No indicating. No

guessing. No scratch test.

PRECISION RESULTS EVERY TIME

The FG5000 Flywheel Grinder takes work pieces

up to 24". With a table diameter of 18" and six (6)

slots in the table, you have the stability and

versatility for a full range of work. The table

support diameter is 15" and the column diameter is

4.44". The vertical head travel of the column is

8.75" with the maximum height of the table to wheel

of 8.75". A strong, 5 horsepower grinding motor at

3,500 revolutions per minute and a 1/4 horsepower

table motor at 16 revolutions per minute mean the

FG5000 Flywheel Grinder is designed to do the

job right.

The standard machine is available in 208 or 230

volts and either single or three phase. Additional

voltages are also available as special order. In

addition, the FG5000 can be ordered with an

optional PowerHead (power column) or with the

PowerHead (power column) and AutoGrindTM

option. The PowerHead (power column) relieves the

operator of the manual movement of the head up and

down. The PowerHead (power column) with the

AutoGrindTM feature powers the head up

and down and can be set to automatically grind the

flywheel to a pre-set depth.

|

The FG5000 Flywheel

Grinder features include:

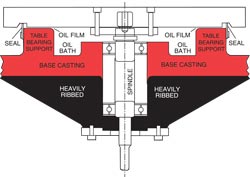

- An exclusive, rugged base casting

with cast-in table support. This means

the table and support are all one piece

solid cast material. More durability,

more reliability.

- Unlimited grinding pressure is

possible without table deflection.

Again, this means you can work the

machine and it will give you the results

you need.

- There is and oil reservoir with an 'Optomatic

oiler' that provides constant

lubrication to the column and table

support.

- There are no thrust bearings or

anti-friction materials that would

require field service.

- The direct table drive means there

are no chains or belts to adjust or

replace. You receive consistent torque

on the table.

- The double cam head swivel lock

gives you positive head lock and is

lubricated for ease in swiveling.

- The optional AutoGrindTM

is easy to set, easy to use and

increases productivity. Best yet, it is

reliable.

The benefits of

owning and using a Van Norman FG5000

Flywheel Grinder:

- You can grind your own flywheels.

You finish the job fast and keep all the

profits.

- You can take in flywheel grinding

business and increase your profits.

- Set up is fast. And it's accurate.

- You can grind most automotive and

light truck flywheels - floor to floor -

in 5-10 minutes. Heavy duty, stepped

flywheels may take longer, but still

profitable.

- The FG5000 Flywheel Grinder

is economical in its' cost and requires

minimal shop space. It is built to last,

costs a few dollars per day to own and

can result in stronger profits.

- You can keep labor costs low. A

skilled machinist is not required to

operate the FG5000 Flywheel Grinder.

It is the easiest machine to operate in

your shop.

- Operating supplies are minimal in

cost.

|

The

unique design of the FG5000 Flywheel Grinder ensures

its longevity and makes it easy to use.

There is

a rugged cast bearing to support the 18" table with

oil reservoir and oil film. The table rotates on the

cast bearing support that prevents any deflection

regardless of the flywheel size and weight or the

grinding pressure.

The oil level is set 1/16" above the table bearing

support for constant lubrication and is maintained

at all times by the unique 'Optomatic' constant

oiler.

There is absolutely no downward or sideways pressure

on the turntable spindle or turntable spindle

bearings, they merely drive and guide the table. (If

the table was only supported by the spindle and

spindle bearings, they would be 'wiped out' by the

downward pressure exerted during grinding).

All this allows you to grind within closer

tolerances.

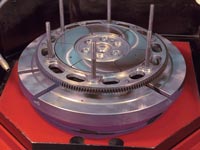

Plunge Grind Fast & Accurately!

Hard spots and heat checks are not a problem. The

entire friction surface is ground simultaneously,

assuring fast, accurate results every time. Plunge

grinding produces a 'swirl' finish and the operator

has total control over the surface finish. The

longer the sparkout, the smoother the finish.

Heavy Duty Construction for better results and

longer machine life.

The FG5000 Flywheel Grinder has a 4.44"

diameter column that is chromed and precision

ground. It is constantly lubricated by a felt wick

installed within the column mounting flange. The

column is totally protected from grinding debris and

coolant by a rubber boot.

The 1.250" lead screw on the Van Norman Flywheel

Grinders is the largest on any flywheel grinder.

The heavy duty bronze lead screw nut is adjustable

to take up any 'play' that may occur throughout the

life of the machine.

The grinding head assembly is set at the factory

with a .023" rear tilt of the grinding wheel and the

side-to-side setting is set at .000" for the fastest

grinding and the best surface finish. The head tilt

can be set flatter for even greater grinding

precision.

The coolant shroud has a removable cap to install

the optional Shop Vac adapter. Using a vacuum

cleaner with the FG5000 Flywheel Grinder will

reduce the mist and grinding debris in the shop.

The Van Norman FG5000 Flywheel Grinder is built

SOLID for RUGGED STRENGTH, PRECISION and

RELIABILITY.

One-piece, 480 pound base casting. The base casting

is the heaviest and most rugged in the industry. The

cast-in column mounting flange is supported by heavy

gussets and all the machining of the base casting is

done with one set-up for maximum accuracy and

perfect perpendicularity.

The column mounting flange is cast integrally for

more strength, stability and perfect alignment. It

has an increased diameter to properly support the

massive column and the column is constantly

lubricated by an internal wick.

Van Norman's exclusive direct drive gear reduction

unit is a rugged, industrial design. The heavy duty

1/4 horse power motor delivers consistent torque to

the table. It requires NO maintenance because it has

no chains or belts to lubricate, adjust or replace.

The exclusive cast-in table support means NO

DEFLECTION - EVER! The 94 square inch table bearing

support has a cast-in oil reservoir and is designed

to prevent table deflection for faster, more

accurate grinding and a superior finish.

Control panels are easy to use, easy to reach and

simple to understand.

One of the most versatile

grinders on the market today, the FG5000 Flywheel

Grinder grinds automotive and import

stepped flywheels, truck flat flywheels and heavy

duty truck stepped flywheels, center plates and

racing clutch components. You can also grind

automatic transmission pump and covers with the

optional ATP5000 Kit.

Consider some of the optional accessories to

further extend the capabilities of your FG5000

Flywheel Grinder.

You can own a 32 gallon coolant tank that

positions next to the FG5000. It has 3-1/2 times the

capacity of the standard tank (9.5 gallons), with

two baffles and three settling compartments -

assuring clean coolant flow to the nozzle. The tank

has a handle and two wheels so it can be rolled away

for easy disposal.

The

optional radius cutter quickly removes the

slight radius left by the grinding wheel on stepped

flywheels. In certain applications, the radius

interferes with pressure plate mounting. The rugged

boring bar removes the radius and produces a square

corner. This heavy duty assembly bolts to the

grinding head casting in holes that are already

drilled and tapped.

Consider

the ATP5000 Kit for automatic transmission

pump and cover rebuilding. The ATP5000 lets you

rebuild parts to close tolerances FAST. With this

kit and the FG5000 Flywheel Grinder, you can

grind bodies and covers from the GM THM700-4R and

the THM200-R4 transmissions. The tooling is precise,

yet easy to use. Save time and money by rebuilding

these parts in house.

Final Details....

The overall height of the FG5000 Flywheel Grinder

is 69" with the height to the table at 34.6". The

width is 34.5" and the front-to-back measures 36".

The weight of the machine is 1,350 pounds. Packaged

for shipping, the weight is 1,500 pounds.

The FG5000 Flywheel Grinder from Van Norman

comes standard with 3 centering cone bolts, 6

centering cones, 4 flange adapters (3" to 5.875"), 4

wheel mounting bolds, wheel spacer, 4" & 6" wheel

mounting flange 3 grinding wheels star dresser,

coolant pump with additive, table lubricant,

leveling bolts and pads, wrenches and more.

Van Norman Flywheel Grinders are manufactured

from the ground up by American craftsmen in a

100,000 square foot manufacturing facility in

Marion, Iowa.

[Download / View Top Fuel &

Funny Car Clutch Kit Instructions]

|