|

Lynx 2000-2500 CNC Orbital Grinder

CNC Orbital Grinder

Lynx

crank and cam grinders line provides a completely new, simple and

flexible solution for grinding crankshafts and camshafts with a

single machine. Grinding main journals, crank pins or thrust faces

is achieved simply without an eccentric chuck. Both concave and

convex cam contours are obtained in a single clamping, without the

use of cam masters simply by using the Lynx software that controls

path machining of the contours.

L'evoluzione della specie

Lynx crank and cam grinders line provides a completely new,

simple and flexible solution for grinding

crankshafts and

camshafts

with a single machine. Grinding main journals, crank pins or thrust

faces is achieved simply without an eccentric chuck. Both concave

and convex cam contours are obtained in a single clamping, without

the use of cam masters simply by using the Lynx software that

controls path machining of the contours.

- A single machine for

crankshafts and

camshaft grinding.

- The most flexible solution for regrinding and for series

production.

- State-of-the-art technology.

- Friendly man-machine interface and very simple machine

operation.

- Effectiveness and cost saving.

Thanks

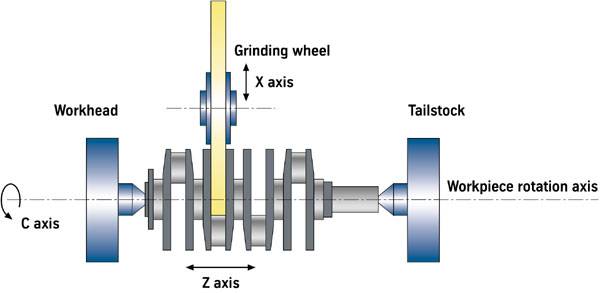

to the CNC and to specific software, crank pins and cam contours

(both negative and positive ones) are achieved by means of tabular

interpolation in the wheel head feed axis in consideration of the

angular position and the elevation value of the workpiece. This

technical solution enables the operator to achieve virtually any

contour, compatible with the grinding wheel shape and machine

geometry, by simple input of specific parametric data.

- A single machine for both

camshaft and

crankshaft grinding.

- Grinding crank pins, main bearings, thrust faces and

flywheel flanges in one clamping of the shaft rotating on its

centers.

- No need for any eccentric chuck thanks to the reciprocating

movement of the wheelhead.

- CNC path controlled machining enables contour grinding of

convex and concave cam contours in a single clamping and without

the need of cam masters.

Adding value to your

products

- Greater dimensional accuracy - roundness, straightness and

angularity - for crankpins, main journals and thrust flanges.

- Superior cam countouring precision.

- Excellent surface finish quality.

- High repeatibility.

- Tighter production tolerances.

The most flexible

solution for regrinding and for series production

- Single clamping grinding for both

camshaft and

crankshafts.

- Simple and easy-to-use man-machine interface with parametric

description of grinding cycles.

- Extremely easy control and operation of the machine, no need

for programming experts.

- Several grinding programs both in manual and automatic.

- Grinding wheel can be dressed into any shape.

- Easy changeover.

- Quick automatic set up.

- Easy integration with any external loading system and other

external measurement devices.

A wide choice of versions to satisfy all your

grinding needs

- Standard version with directdrive work-head, rotating

tailstock and manual clamping of the shaft.

- Production version with direct drive work-head, rotating

tailstock and automatic clamping for production of small-medium

size crankshaft and camshaft.

- Production version with

direct

drive work-head, motorized tailstock and automatic clamping by

means of retracting jaws for prodution of

medium-large size crankshaft.

- fixed tailstok and second "retractable"wheelhead for concave

cams grinding.

Effectiveness and Cost Saving

- Lower capital costs (one machine for both

crankshaft and

camshaft).

- Considerably reduced production times (single clamping).

- High cutting capacity.

- High productivity.

- Saving of production space.

- Minimized grinding tools costs.

- Low investment: minimum cost equipment suitable to your

grinding volume.

State-of-The-Art Technology

Machine Base

Lynx crank and cam grinders line has been developed using

sophisticated 3D modeling programs and

FEM analysis in order

to optimize the rigidity of the cast iron base and better dampen

vibrations.

- Unique one piece of cast Iron base.

- Optimized design for best damping characteristic.

- Very high strength and rigidity.

- A system for thermoregulation of the base ensures maximum

dimensional stability.

Wheelhead

- Lynx crank and cam grinders line features a motorized

spindle with an integral direct drive. Direct drive guarantees a

compact construction and improved dynamic rigidity.

- Fully automatic balancing system and vibration detector for

best cutting condition of the grinding wheel, higher accuracy

and quick changeover.

- Linear motor technology with direct drive of the X axis

(reciprocating movement of the wheelhead) resulting in improved

accuracy and higher rigidity of the hydrostatic drive train (no

transmission errors and wear effects).

- Full digital drive technology and a high resolution glass

scale guarantee excellent synchronization characteristics, fast

and accurate positioning, and high dynamics for rapid wheelhead

and table movement.

- Liquid cooled drives for best heat dissipation and zero

contamination.

- Rolling guides for high rigidity even in the most severe

applications.

- Linear encoder at the X axis resulting in min command

increment of 0.1µ.

Grinding wheels

Based on type of grinding Linx 2000can be fitted with:

- Conventional grinding wheels peripheral speed up to 35m/s,

ideal for the production of small batches.

- Sintered ceramic grinding wheels-speed up to 63m/s offering

higher resistance to wear and providing high removal capacity

suitable for large size batches.

- highly productive CBN (cubic Boron Nitride) grinding

wheels-speed up to 120m/s-for maximum machining capacity ,

tighter tolerances and particularly suitable for series

production.

Workhead

- Chatter free grinding produces a perfect surface quality. We

have designed a

motorized

spindle to achieve this with a direct drive to the

C-axis.

- Direct drive of the workpiece spindle guarantees a compact

construction, improved accuracy, reliability and higher rigidity

of the drive train (no transmission errors and wear effects).

- Full digital drive technology and a high resolution rotary

encoder guarantee excellent synchronization characteristics and

high dynamics.

- Liquid cooled drive for best heat dissipation and zero

contamination.

- Rolling guides for high rigidity even in the most severe

applications.

- Encoder at the C axis resulting in min command increment of

0,0001 deg.

- Spindles with manuals clamping, automatic clamping and

automatic

clamping by means of retractable jaws in order to

satisfy any possible grinding need.

Tailstock

- Optimized dimensions and solidly bolted on the table for

maximum rigidity.

- Slide mounted tailstock with 50mm stroke is able to

accommodate complete workpiece families without the need to

re-set.

- It features a hydraulic quill retraction by foot pedal for

easy workpiece clamping.

- Rotating

tailstock with rolling bearing, motorized tailstock and

fixed

tailstock for concave cams grinding are available.

Work-table

- Linear motor technology with direct drive of the Z axis

resulting in high dynamics, improved accuracy, higher

reliability and rigidity of the drive train (no transmission

errors and wear effects).

- Full digital drive technology and a high resolution linear

encoder guarantees excellent synchronization characteristics,

fast and accurate positioning, and high dynamics.

- Min command increment of 0.1µ.

- Linear rolling guides ensure higt rigidity even in the most

severe applications and prevent the "backlash" phenomenon

typical of hydrostatic systems.

Optional Equipment

- Wide range of

"follow down"

hydraulic steady rests to accomodate shaft diameters

from 20 to 125 mm.

- Marposs

measuring

device for "in-process" control of main bearings, crank

pin diameters.

- A second

Retractable wheelhead for grinding concave cams. It

features direct drive motor which enables installation of

grinding wheels with a diameters from 38 to 100 mm.

- A cartesian

manipulator (gantry) enables automatic workpiece loading

and unloading.

- A cooling and cooling-lubrication device.

CNC

- Simple program input via keyboard, tape or disk.

- Background editing and programming for increased

productivity.

- Gauging of main and crank pins diameter and thrust faces,

enable crankshaft measuring and generation of the grinding

cycle.

- Contour gauging enables cam profile mapping and grinding

profile generation without the need of the cam master.

- Cam profile and the valve opening curve can also be

varied/corrected via CNC built in functions.

Operating Controls

- The intuitive, ergonomic and logical arrangement of the

operating control

ensures most convenient operation.

- The

portable PCU-terminal enables machine operation in safe

conditions while closely checking on the grinding operation.

Safety Features

Safe operation is ensured by

- Touch

detector for continuous monitoring of the contact

between grinding wheel and workpiece, grinding wheel and

dressing device results in minimal non-cutting times. The device

works also as Integrated collision detection system.

- The wheel spindle drive motor control incorporates a load

meter so that if the pre-set limits are passed, an overcurrent

condition will initiate an emergency stop.

- Two front sliding doors for full enclosure of the working

area during machine grinding operation.

- During loading/unloading of the workpiece (front doors are

open), two fences/panels automatically separate the working area

from the wheelhead (that slides all the way back along the X

axis) and the operator is fully protected even with the grinding

wheel rotating.

- Lynx2000 has been built according with the CE norms and EMC

directives regulating manufacture of machine tools.

- All safety features have been arranged in such a way as not

to hinder the ergonomy of the machine and the production of the

operator.

Grinding

Simple and easy-to-use

man-machine interface with

parametric description of

grinding cycles.

Extremely easy control and operation of the machine, no need for

programming experts.

Comfortable operation by means of Lynx software programs and

operator support by easy to use menu technique.

Control and simulation of the generated grinding cycle in real time.

- Manual & automatic.

- Cylindrical grinding (oscillation of the table on the Z

axis).

- Plunge cut and multi-plunge cut grinding.

-

Orbital grinding of crankshafts (reciprocating of the

wheelhead on the X axis following the workpiece rotation on the

C axis).

- Cam contour grinding.

-

Concave Cam grinding, with

2nd grinding

wheel.

- CAMVIEW is a specific

program that enables the operator to view the difference between

the theoretical and actual contour of the cam. With this utility

it is possible to modify the deviation between the two curves by

also calculating and viewing the effect it will have on the

valve opening law.

Wheel Dressing Programs

Wheel dressing device via CNC to obtain almost

any grinding wheel

profile. The radius can be dressed both on left and on right

wheel sides, for straight or angular infeed. The file with the

dressing program to shape the wheel can also be imported via

external interface.

Graphical generation and simulation of the grinding wheel profiling

operation is standard.

Available functions:

- Dressing compensation.

- Compensation of the grinding wheel diameter.

Dressing Options

The operator has various possibilities to select the time for

dressing:

- After the programmed switchover points.

- After a programmed number either of machined parts or of

grinding operations.

Dressing Device

- Three dressing devices (for front, right and left side)

installed on the tailstock.

-

Rotating diamond wheel (available upon request).

We Care

Service

After your decision for investment, Berco will always be standing by

with their quick and competent After Sales Service. Expert

technicians will be able to solve your problems while an efficient

logistic organization will be able to quickly deliver spare parts

wherever you need them.

Maintenance

- Accurate and precise manuals.

- Easy access to complete interior.

- Easy to service.

- Operator friendly for flexible grinding.

- Modular structure.

- Improved maintainability.

Leadership in environmental development

Not only do we care about our customers, supplying quality machines

manufactured since '91 under

ISO9001

certified process, but we also care about the environment. Since Jan

2000, Berco is

ISO14001 certified and has adopted Environmental Procedures

throughout the entire manufacturing process. We have an

Environmental Strategy and we continuously check on the progress

made toward the set objective.

orkpiece

| |

Lynx 2000 |

Lynx 2500 |

Lynx 2500 HD |

Max grinding diameter in

orbital grinding = Dp+S (#) |

mm 220 |

mm 300 |

mm 400 |

Max grinding diameter in

cylindrical grinding |

mm 300 |

mm 300 |

mm 400 |

| Max. swing over table |

mm 300 |

mm 300 |

mm 400 |

| Steady rest min./max. diameter (*) |

mm 20/125 |

mm 20/125 |

mm 20/125 |

Max. workpiece weight

between centers |

kg 135 |

kg 200 |

kg 400 |

| Centers height |

mm 270 |

mm 270 |

mm 310 |

| Max. distance between centers |

mm 1700 |

mm 2500 |

mm 2500 |

Max. grinding length

(tailstock with rolling bearings*) |

mm 1500 (1300*) |

mm 2500 |

mm 2500 |

| Self-centering chucks diameter |

mm 180/210/260 |

mm 180/210/260 |

mm 180/210/260 |

| Slide mounted tailstock stroke |

mm 50 |

mm 50 |

mm 50 |

| Automatic Balancing Device |

Programmable |

Programmable |

Programmable |

(#) Dp = crank pin diameter;

S = pin stroke

(*) Option |

Grinding Wheel

| |

Lynx 2000 |

Lynx 2500 |

Lynx 2500 HD |

| Max. Diameter |

mm 660 |

mm 660 |

mm 850 |

| Min./Max. Width |

mm 20/80 |

mm 20/80 |

mm 20/80 |

| Max. Surface Speed |

m/sec 35/63/120 |

m/sec 35/63/120 |

m/sec 35/63/120 |

Wheelhead (X axis)

| |

Lynx 2000 |

Lynx 2500 |

Lynx 2500 HD |

| Drive and guideway |

Linear Motion System |

Linear Motion System |

Linear Motion System |

| Stroke |

mm 490 |

mm 490 |

mm 490 |

| Positioning system |

Optical |

Optical |

Optical |

| Min. input increment |

mm 0.0001 |

mm 0.0001 |

mm 0.0001 |

Workhead (C axis)

| |

Lynx 2000 |

Lynx 2500 |

Lynx 2500 HD |

| Workpiece speed rotation

range |

rpm 1-1000 |

rpm 1-1000 |

rpm 1-1000 |

Workpiece speed rotation

range for contour grinding |

rpm 1-400 |

rpm 1-400 |

rpm 1-400 |

| Torque at spindle |

Nm 250 |

Nm 250 |

Nm 250 |

| Positioning system |

Encoder |

Encoder |

Encoder |

| Min. input increment |

deg. 0.0001 |

deg. 0.0001 |

deg. 0.0001 |

Table (Z axis)

| |

Lynx 2000 |

Lynx 2500 |

Lynx 2500 HD |

| Drive and guideway |

Linear Motion System |

Linear Motion System |

Linear Motion System |

| Positioning system |

Optical |

Optical |

Optical |

| Min. input increment |

mm 0.0001 |

mm 0.0001 |

mm 0.0001 |

Drive motors

| |

Lynx 2000 |

Lynx 2500 |

Lynx 2500 HD |

Grinding wheel spindle

(built in direct drive) |

kW 25 |

kW 50 |

kW 50 |

Workpiece spindle

(built in direct drive) C axis |

kW 7 |

kW 7 |

kW 7 |

General Data

| |

Lynx 2000 |

Lynx 2500 |

Lynx 2500 HD |

|

Width A |

mm 5500 |

mm 7680 |

mm 7680 |

|

Depth B |

mm 2600 |

mm 2600 |

mm 2600 |

|

Height C |

mm 2000 |

mm 2100 |

mm 2100 |

| Weight |

kg 11000 |

kg 15000 |

kg 15000 |

|

Are you trying to inquire about a part

or check availability of a product or a solution service?

Please either call / WhatsApp (60) 19 333 9484 at or email us at

wso@assurich.com.my

or submit an enquiry form

online. |

|