|

WS2

Working Diameters

With Standard Equipment

IN-LINE BORING

Starting from ø 42 mm to over ø 400 mm

OVERLAY WELDING

Internal– from ø 25 mm to over ø 400 mm

External- from ø 20 mm to over ø 400 mm

Drilling – from ø 5mm to max ø 45 mm

Tapping – from ø 8mm to max ø 45 mm

with presetting for Tapping

Accessory kits

KIT 20

For in line boring starting from ø 22mm to ø 45mm

KIT 30

For in line boring starting from ø 32mm to ø 60mm

KIT 2000 from ø 45 mm to ø 400 mm

For facing bosses, creating circlip grooves, external machines.

Upon request, we can supply:

• Personalized kits for specific machining or applications.

Photo Gallery

WS2

Video gallery application

•

Drilling - WS2

•

In line boring - WS2

•

External surfice machining

•

Set-Up: In line borning

• Set-Up: Overlay welding

• Set-Up: Centering

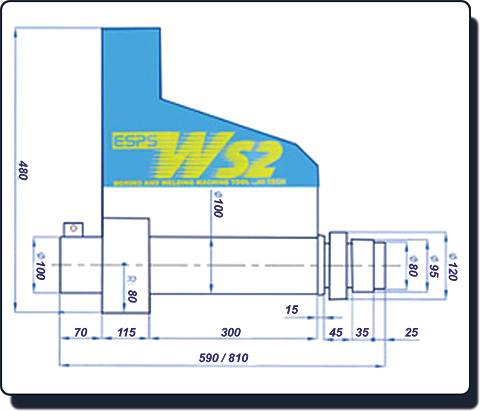

Machine Size

| Technical Characteristics |

| The

machine is equipped with an electronic control panel with

diagnostic display |

|

TOOL HOLDER SHAFT

DIAMETER |

mm |

40 ( 1,57 in

) |

|

TOOL HOLDER SHAFT LENGTH |

mm |

2600 usable mm (N° 3

connectable bars (1000mm+1000mm+730mm) |

|

BORING DIAMETER |

mm |

22 - 400 ( 0,87 in -

15,75 in ) |

|

WELDING DIAMETER |

mm |

25 - 400 ( 0,98 in -

15,75 in ) |

|

WELDING TECHNOLOGY |

|

SPIRAL (CONTINUOUS WITH

VARIABLE STEP) |

|

LONGITUDINAL STROKE |

mm |

UNLIMITED WITH STEP OF 220

mm (8,66 in) |

|

ROTATION MOTOR |

mm |

C/C (CE COMPLIANT) |

|

FEED MOTOR |

mm |

C/C (CE COMPLIANT) |

|

FEED SYSTEM |

mm |

ELECTRIC-MECHANICAL |

|

OUTPUT TORQUE AT THE BAR |

mm |

290 Nm (266 Rpm) |

| MAX

ROTATION SPEED |

rpm |

266 |

|

FEED RATE |

mm/rpm |

0 - 0,5 ( 0 – 0,02 in / rev

) |

| MAX

FEED SPEED(w/rapid button) |

mm/min |

285 |

|

REMOVAL MATERIAL |

cm³/min |

23 |

|

DRIVE UNIT WEIGHT |

kg |

34 |

| Standard Equipment |

| N°1 DRIVE UNIT

|

| N° 1 CONTROL

PANEL |

| N° 1 CABLE FOR CONTROL

PANEL |

| N° 1 CONTROL

PANEL HOLDER |

| N°3 CONNECTABLE TOOL-HOLDER

SHAFTS Ø 40 MM lgth 1000 mm + 1000 mm + 730 mm:Tot. Usable

lgth 2600 mm |

| N°4 BEARING

CARRIERS |

| N°24 BRACKETS FOR ADJUSTING

DIAMETERS (N° 12 X 50 MM, N° 6 X 100 MM, N° 6 X 180 MM)

|

| N° 1

CENTERING KIT (2 RINGS - 6 BOSSES - 6 SCREWS M10x60 mm) |

| N°6 THREADED BARS M10x250

MM FOR THE CENTERING KIT |

| N° 5 CARBIDE

INSERTS |

| N° 1 TOOL-HOLDER S10Cx50 mm

(COMPLETE WITH WRENCH AND TORX SCREW) |

| N° 1

TOOL-HOLDER S12Cx80 mm (COMPLETE WITH WRENCH AND TORX SCREW) |

| N° 4 TOOL-HOLDER EXTENSIONS

(Ø 90 MM + Ø 150 MM + Ø 230 MM + extension KNUX type lgth

100 MM), |

| N° 1 SMALL

HOOK ø 35mm (device for regulating cutting depth of tool

holder) |

| N° 1 MICROSPAND (MODULAR

DEVICE USED FOR INTERNAL MEASUREMENTS) |

| N°3 MICROSPAND EXTENSIONS

(n° 1) 100 MM + (N° 2 ) 50 MM |

| N°1

COMPARATOR 1/100 |

| N°1 COMPARATOR EXTENSION |

| N°2

COMPARATOR HOLDER 8/8 – 10/8 |

| N°1 WELDING TORCH CABLE

WITH EUR-FITTING |

| N°1

TELESCOPIC WELDING TORCH SHAFT Ø 40 MM Tot. Lgth. 1500 mm |

| N° 4 TORCH

HEADS FOR INTERNAL OVERLAY WELDING C/W WELDING WIRE NOZZLES

AND GAS DIFFUSER (B 125 MM x C 90 MM x G 180 MM x M 70 MM) |

| N° 1 TORCH HEAD FOR

EXTERNAL OVERLAY WELDING C/W WELDING WIRE NOZZLES AND GAS

DIFFUSER (A 320 MM) |

| N° 3 TORCH

HEAD EXTENSIONS (D 55 MM x E 45 MM x H 135 MM) |

| N°1 LATHED WELDING WIRE

NOZZLE Ø 0,8 MM |

| N° 2 SHORT

WELDING WIRE NOZZLE Ø 0.8 MM – 1 MM |

| N° 2 LONG WELDING WIRE

NOZZLE Ø 0.8 MM – 1 MM |

| WRENCHES

|

| OPERATION MANUAL |

| N° 1 TROLLEY

(for containing all the standard kit) |

Equipment upon Request

| KIT |

|

| KIT ø 20 mm |

For

boring starting from Ø 22 mm up to Ø 45 mm

Composed of:

· N° 2 connectable tool-holder shafts ø 20 mm length.

1000 mm + 1000 mm: Tot. Usable lgth. 1950 mm

· N° 3 adapting bushings ø40xø20x80 mm

· N° 1 adapting bushings ø40xø20x90 mm

· N° 1 adapting bushings ø40xø20x150 mm

· Centering kit composed of:(N° 2 rings ø 20 mm -N° 6

bosses M10 -N° 6 screws M10x60 mm

· N° 1 tool holder S08 (COMPLETE WITH WRENCH AND TORX

SCREW)

· N° 1 comparator holder 8/8

· N° 1 hexagonal wrench 3 mm |

| KIT ø 30 mm |

For boring starting

from Ø 32 mm up to Ø 60 mm

Composed of:

· N° 2 connectable tool-holder shafts ø 30 mm length.

1000 mm + 1000 mm : Tot. Usable lgth. 1950 mm

· N° 3 adapting bushings ø40xø30x80 mm

· N° 1 adapting bushing ø40xø30x90 mm

· N° 1 adapting bushing ø40xø30x150 mm

· Centering kit composed of: (N° 2 rings ø 30 mm -N° 6

bosses M10- - N° 6 screws M10x60 mm

· N° 1 tool holder S10C 33 mm |

| KIT 2000 ø 40

mm |

For

facing bosses, creating circlip grooves, external machining

from Ø 45 mm up to Ø 400 mm

Composed of:

· N° 1 gear box

· N° 3 brackets 30x25x270 mm

· N° 3 brackets 30x30x305 mm

· N° 1 fixed wrench 19 |

Upon request we can

supply personalized kits for specific

machining or applications

CERTIFIED TEST – STEEL C45

|

DIAMETER |

mm |

Ø 100 |

Ø 300 |

|

CUTTING DEPTH |

mm |

5 in the

radius

10 in the diameter |

3 in the

radius

6 in the diameter |

|

FEED SPEED |

mm/min. |

20 |

8 |

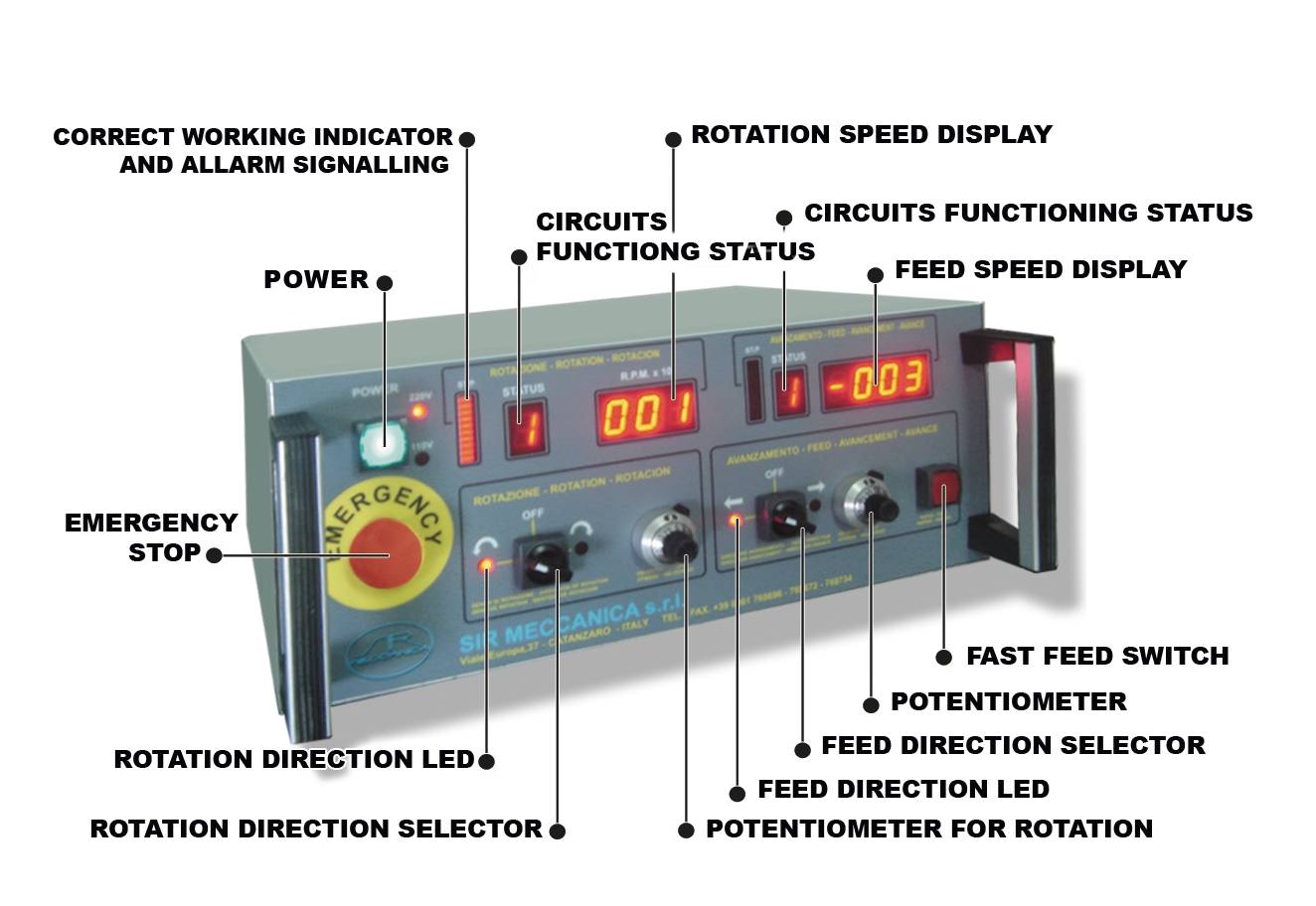

Control Panel An electronic circuit has been inserted

to guarantee a major safety in operation and to safeguard the rotation motor

from excessive strain in case of an incorrect setup of the parameters, as well

as to compensate possible critical points in machining. It automatically and

proportionally reduces the feeding speed to reach the maximum strain point of

the rotation motor, in order to dynamically reduce the load of the work, without

passing the stop point for protection.

Thanks to the led bar called STP, it is possible to constantly monitor the

motor’s work load, so to be able to optimize the choice of the parameters

(rotation speed and feed speed), based on the hardness of the material, the

type of tool being used, to the machining diameter and to routing diameter of

the tool. Furthermore, the bar signals in advance the alarm condition and the

subsequent shut down of the control panel, flashing until the working conditions

are restored.

The technical characteristics include:

AC 110 ~ 220 50 / 60 HZ WITH AUTOSELECTION OF MAINS VOLTAGE, WITHOUT THE USE

OF TRANSFORMERS OR INVERTERS; ELIMINATING ELECTROMAGNETIC INTERFERENCES

ESPS ® TORQUE ELECTRONIC RUNNING OF THE TWO MOTORS WITH ELECTROMECHANIC

SYNCHRONIZATION

DISPLAY FOR SPEED OF ROTATION REVOLUTIONS

ACOUSTIC WARNING WITH DISPLAY WITH FIGURED SIGNALS OF POSSIBLE FAULTS DURING THE

RUNNING OF THE ROTATION MOTOR

DISPLAY FOR SPEED OF FEEDING REVOLUTIONS

ACOUSTIC WARNING WITH DISPLAY WITH FIGURED SIGNALS OF POSSIBLE FAULTS DURING THE

RUNNING OF THE FEEDING MOTOR

MAIN SWITCH

EMERGENCY SWITCH

INVERTER DX/SX FOR FEEDING

INVERTER DX/SX FOR ROTATION

POTENTIOMETER FOR ROTATION REGULATION

POTENTIOMETER FOR FEEDING REGULATION

SWITCH FOR RAPID TRANSLATION OF THE SHAFT

|

Are you trying to inquire about a part

or check availability of a product or a solution service?

Please either call / WhatsApp (60) 19 333 9484 at or email us at

wso@assurich.com.my

or submit an enquiry form

online. |

|