| Engine Dynamometer System |

| SuperFlow |

Chassis Dynamometers

Engine Dynamometers

Flowbenches |

| |

|

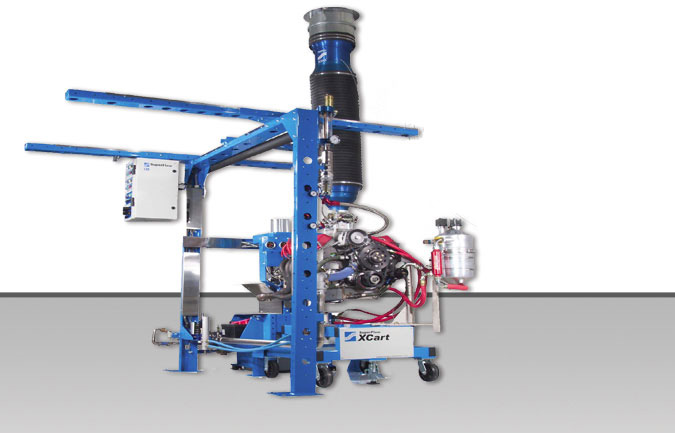

NSCR Engine Dyno

Engineering-grade Docking Dynamometer

Perform extremely repeatable, automated engine tests with rapid

testing throughput and precision oil and coolant management.

SuperFlow's NSCR test system has been selected by the world's top

racing organizations as the standard for testing their production

engines. Users report reduced engine test and installation time, and

a test series repeatability envelope as good as 0.2% at maximum

power.

The XConsole controls all aspects of the automated test, and

eliminates many sources of test-to-test variability. Coolant and oil

temperatures can be computer controlled for optimum test

repeatability. The engine can be automatically filled with

pre-heated water, and automatically drained at the end of the test.

The NSCR XConsole System automates your testing for more consistent

results with less operator interaction. Automated load and

electronic throttle control help provide repeatable test sequences

and free the operator to monitor live test data. SuperFlow's

automated tests support one-button testing. Start the engine, warm

it up, run the test series, bring it back to idle, and shut it off.

All data will be automatically recorded, saved, and displayed in

overlay-graphs on the computer. Built-in Safety Limits help protect

the engine from harm.

The NSCR system's WinDyn software provides quick and easy test

design and configuration, real-time data acquisition and display,

and convenient test-data management, display and reporting.

Changes in coolant and oil temperatures can add or subtract

horsepower from a dyno pull on identical engines under otherwise

identical conditions.

SuperFlow's oil and coolant temperature control systems hold these

temperatures to �3� F (�1.7�C) to help keep your tests VERY

repeatable. These systems also help you mimic conditions that you

would expect on the track and keep them that way, to provide a more

realistic testing scenario. Finally, these systems allow you to

preheat the block with hot water for shorter warm-up periods and to

drain the system once the test series is complete for faster engine

test changes.

Recommended Options:

- Automated Temperature Controller Panel and Drivers

- 4000P-6032 Dyno Start package

Features:

- Two (2) XCart docking engine carts with removable drip

tray and drain plug

- Floor mount docking cart alignment base

- SF-871 heavy-duty water brake absorber, 2,500 HP (1864

kW) rated capacity, outlet controlled, low-inertia, with

4-bolt servo valve

- Interface load cell, 1000 lb.-ft. (1356 N-m) capacity,

temperature compensated (2,000 lb-ft. optional)

- Rotary electric throttle actuator system

- Engine Control Panel (starter, ignition, fuel pump

controls with autoresetting fuse protection, LED's indicate

on, or tripped relay status)

- Your choice of input shaft: 1.125" x 10-tooth spline,

1.375" x 10-tooth spline

- High performance fuel pump, two fuel regulators, 0-800

lb/hr (100 g/s)

- Convenient rail support system for integrated plumbing

and cable routing

- Oil and Coolant heat exchangers, racing oil filter, oil

and coolant flow turbines, pre-plumbed. Two thermocouples

for temperature monitoring. Cooling system has air bleed

bubble tower, quick disconnect lines, and quick fill

provisions. Can be used with optional computerized

temperature controls for automated control from console.

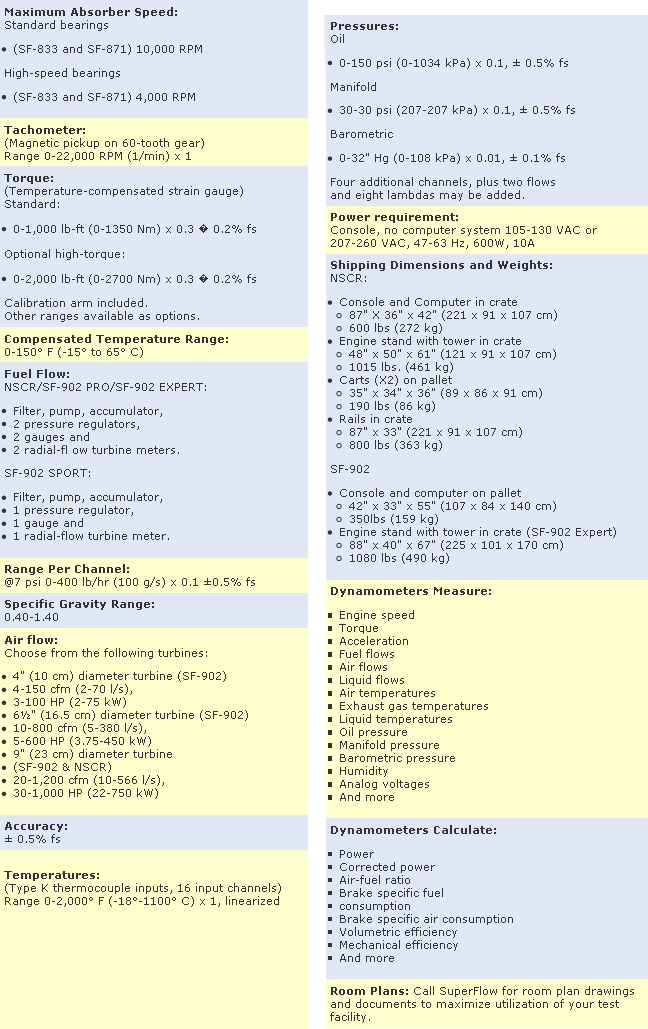

Specifications:

More Info:

Downloads Downloads

|

Are you trying to inquire about a part

or check availability of a product or a solution service?

Please either call / WhatsApp (60) 19 333 9484 at or email us at

wso@assurich.com.my

or submit an enquiry form

online. |

|