| Engine Dynamometer System |

| SuperFlow |

Chassis Dynamometers

Engine Dynamometers

Flowbenches |

| |

|

SF-902 Engine Dyno

Engine Dynamometer

The SuperFlow SF-902 is

the next generation engine

dynamometer for all levels

of engine builders. The

SF-902 replaces our sturdy,

industrial-duty SF-901

system that has proven

itself over and over during

the past 20+ years. Equipped

with our super-fast

electronics package and our

unique engine cart/engine

stand, the SF-902 is simply

the most versatile engine

dynamometer system on the

market. Period.

SuperFlow's XConsole Classic

provides state-of-the-art

control and data acquisition

capabilities. Internal

system communication is done

through CAT5 computer

cables, and all gauges and

meters can be removed and

replaced from the front

panel.There are no wiring

harnesses or card-edge

connectors on the XConsole

Classic. The XConsole

Classic can be outfitted

with a variety of gauges to

suit your needs. We include

cut-outs for standard

AutometerT gauges. Large LCD

screens show live data,

lighted rocker switches

control engine and test cell

equipment, and panel meters

display torque, speed,

power, or any other

important data.

Our highly-acclaimed

WinDyn software is included

at no charge. WinDyn

provides quick and easy test

design and configuration,

real-time data acquisition

and display, and convenient

test-data management,

display and reporting.

The dynamometer can be

configured as a roll-around

engine stand like the old

SF-901 or you can set it up

with docking carts.

Use the SuperFlow SF-902

to measure power

characteristics of your

engines. It will tell you

not only how much power, but

where the power is in the

speed range. For performing

research and development,

you can evaluate

modifications one at a time,

or as a complete system.

For race engines, you can

ensure that the engine is

right before it runs on race

day. Develop on the dyno,

race at the track. Whatever

the engine's purpose, you

can use the dyno to perform

a quality audit. You ensure

that the engine does what

it's intended to do.

Quantify the results of your

modifications. Prove that

you've built the engine you

meant to build.

- New operator console

puts everything at your

fingertips.

- Choose docking cart

or mobile dyno

configuration.

- Roll-around,

wall-mount or optional

boom-mounted sensor and

control box are close

for testing, and

out-of-the-way when you

need room to work.

- New data acquisition

and control system is

faster and gathers more

data.

- Absorber works over

a wide range of engine

speeds and outputs,

offering precise control

for any acceleration

rate.

- Optional

computer-controlled oil

and coolant temperature

systems.

- Optional dual

starter.

Features:

60-inch (1.5 m) engine stand with large casters. Narrow

uprights for exhaust clearance

SF-833 water brake absorber, 1500 HP (1125 kW) rated

capacity, outlet, controlled, low-inertia, with 4-bolt servo

valve Interface load cell, 1000 lb.-ft. (1356 N-m) capacity,

temperature compensated (2000 lb.-ft. optional)

Hydraulic throttle actuator system

- Your choice of input shaft:

- 1.125" x 10-tooth spline

- 1.375" x 10-tooth spline

- 1.125" x 26-tooth spline

Data Acquisition and Control System

- Pro data acquisition and control box

- Interconnect panel with 2 pre-configured analog inputs

(Lambda)

- Integrated real-time weather station (air temperature,

barometric pressure, humidity)

- WinDyn™ software

- System can run automated tests; Requires a computer

system to save, view, and print test data

Operator's table with manual throttle control, large enough

for a monitor, computer keyboard, and mouse

1 day of training*

Popular Options

- 16-channel thermocouple panel and 8 exhaust gas

thermocouples

- 10-channel pressure panel with two pressure transducers:

0-150 psi and -15/+85 psi

- Engine control panel - relays for ignition, starter, and

fuel

- Single-channel fuel system (fuel pump, regulator, fuel

turbine)

- Mini tower computer system, 17" CRT monitor, color

printer

And many more... * Travel costs, travel time and expenses not

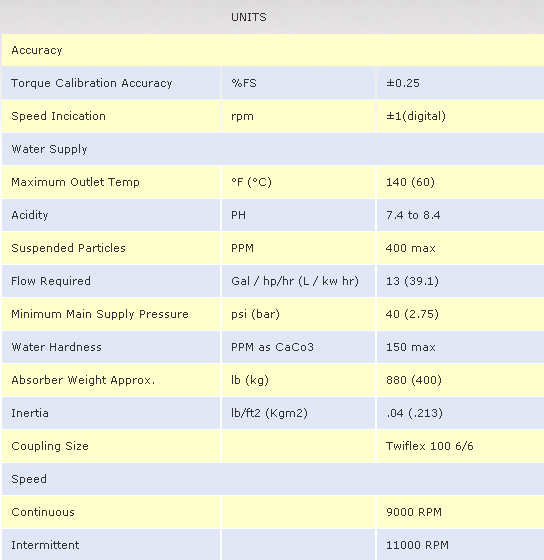

included. Specifications:

More Info:

Downloads Downloads

|

Are you trying to inquire about a part

or check availability of a product or a solution service?

Please either call / WhatsApp (60) 19 333 9484 at or email us at

wso@assurich.com.my

or submit an enquiry form

online. |

|